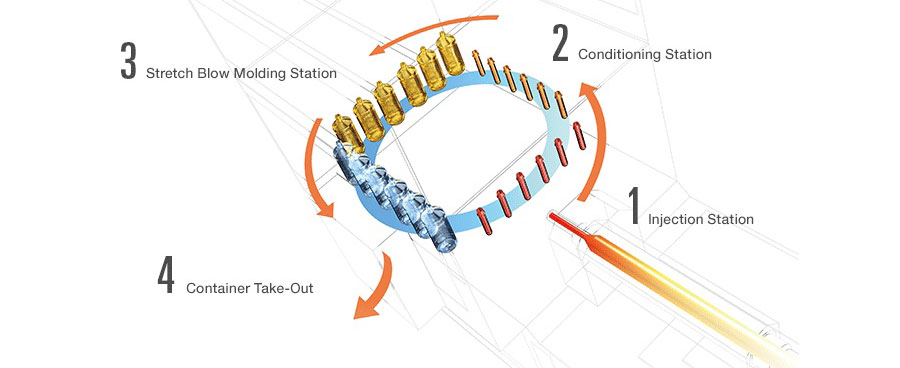

Processo de Produção

O processo original de 1 etapa desenvolvido pela ABS.

Ao utilizar o calor residual do processo de moldagem por injeção de pré-formas, o consumo de energia do processo de 1 etapa é significativamente menor do que o necessário para a moldagem de 2 etapas.

A flexibilidade das máquinas convencionais de 1 etapa da Série ASB é ideal para moldagem personalizada extrema e aplicações não PET.

| As pré-formas são injetadas e resfriadas abaixo da temperatura de cristalização do PET, mas retêm calor suficiente para serem sopradas sem necessidade de reaquecimento adicional. Designs especializados de pré-formas e ajustes nos parâmetros de injeção podem ser usados para otimizar a distribuição de material nos recipientes acabados. Como a pré-forma é projetada especificamente para cada recipiente, características especiais, como gargalos não padronizados, podem ser facilmente incorporadas. |

| Aqui é onde a lendária flexibilidade e estabilidade da Série ASB se originam. Uma variedade de tecnologias pode ser aplicada para otimizar o perfil de temperatura da pré-forma, permitindo a máxima utilização do material, possibilitando a moldagem de recipientes leves e resistentes em uma variedade de materiais. Ao trocar essas peças de baixo custo, recipientes redondos, quadrados ou ovais podem ser facilmente produzidos a partir de uma pré-forma comum, sem a necessidade de modificar peças mais caras do molde de injeção. Esta estação também pode compensar as variáveis externas, como fornecimento de utilidades, condições ambientais e resinas de moldagem, oferecendo assim uma moldagem mais estável. |

| O processo básico de moldagem por sopro pode ser modificado de várias maneiras. Os mais comuns entre eles são o ajuste de temperatura e a formação ou inserção de alças. Se o design da pré-forma for compatível, uma variedade de formas de recipientes pode ser formada apenas mudando o molde de sopro. |

| Os recipientes são ejetados da cavidade do lábio, tendo sido precisamente mantidos desde a injeção da pré-forma. Os gargalos são orientados com precisão durante todo o processo de moldagem e são protegidos contra arranhões ou danos. O corpo também é mantido livre de arranhões, de modo que a aparência do recipiente é incomparável, tornando esse processo ideal para aplicações que exigem a mais alta qualidade visual. |